NRS MOLD READY

NRS MOLD READY TECHNOLOGY

IMAGES

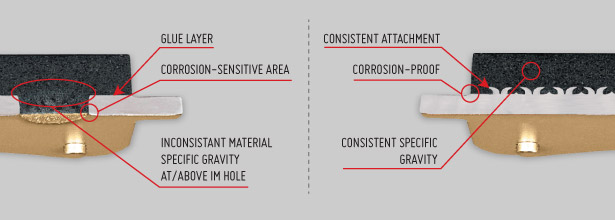

The impact of the NRS Mold Ready Plate

The NRS technology enables us to manufacture the Mold Ready Plate – a pre-coated or pre-treated NRS-applied plate – allows the removal of pre and post molding operations, bringing a greater simplicity to all aspects of the friction production process. As well, the nature of the coating provide greater accuracy on critical dimensions.

Return to simplicity

• Less plate deflection

• A less complex manufacturing process

• More consistent abutment span dimensions

• Elimination of “Rust Jacking”

• Fewer enviromental concerns

• Options to increase rust protection to levels above paint

Rethink the foundation

While the development of IM overcame many of the negative characteristics inherent in riveted disc brake pads, it added multiple layers of complexity to the pad manufacturing process – and problems of its own. The development and/or improvement of what we call “NRS Enabling Technologies” now brings opportinity to render the cost and time burdens typical to IM pad manufacturing obsolete and make possible the NUCAP Mold Ready Plate.

HEX free & FNC coatings

INQUIRE ABOUT NRS MOLD READY

Have a few questions you need answered drop us a line.